FAQ

Head Gasket Failures

I suspect that the vast bulk of the head gasket issues are related to 2 problems:- Many BRAND NEW heads are out of spec because when they are surface ground flat, they were doing so with either not enough coolant, machining too quickly, or taking too deep of a pass. This transfers heat into the part. Heat is the ENEMY when surface grinding. Like all matter, when something gets hot, it expands. So, machining too fast, too deep, or with not enough coolant, the part WILL expand. Then that expanded material is machined flat. Then, the part cools! After it cools, the material shrinks, and now you are left with a concave surface! KTM tried to resolve this by moving the production of the heads and cylinders to Austria, but I've still encountered brand new heads which were made in Austria which were STILL out of spec when brand new out of the box. Testing the Head and Cylinder around the perimeter on a flat surface with 0.10mm (0.004inch) feeler gauges (see Service Manual Sections 14.6.8 and 16.4.10), or shining a bright light, is NOT sufficient of a test. This is because the material which is concave is NOT on the edges. It's the internal flat area which was expanded when hot, and then shrank. To test this, you need a machinist straight edge, machinist square, machinists level, or a surface plate which is blued up and checked for contact area. If you don't have a surface plate, you can use granite counter tops, thick plate glass, or a granite tile of at minimum 12 inch square and 1/4 inch thick. You can sometimes get "sink cutouts" from granite countertop installers for free, so if you don't have granite countertops, and you don't want to invest in a rarely used granite surface plate, that's probably your best option.

- The bolts that Bajaj uses for the heads are abject garbage! They can be stretched to yield during the torque, but not all bolts HOLD that torque and will stretch after they are torqued down. This results in a bolt which isn't torqued to spec, and POP goes the head gasket after some amount of heat cycles, depending on how bad the bolt is. This is also why NEW head bolts are encouraged to be used any time you pull the head. Officially, the head bolts are not one time use, but in practice and in the field, it's become VERY obvious that they are not always safely re-usable. The best way to test this is with an analog torque meter. This is the style of torque wrench which has a bending arm with a needle which points to the torque value being applied.

These two issues EASILY explain almost ALL of the head gasket failures, outside of racing. In racing applications, yeah... you can pop head gaskets. It happens. However, the two above issues can still strike even a "perfectly" prepared race motor if the head has a concave surface or the head bolts stretch too much or don't hold torque. You should check the torque of the bolts with an analog torque strain gauge. Clicker torque wrenches are very difficult to use to verify actual torque on the head bolts. Also, if the bolts were not lubricated, or the threads were not perfectly formed or gritty, the additional friction can give a false reading of a higher torque value than was actually achieved. With conditions at Bajaj being... well... 3rd world... it's EASY to see how head bolts are not being torqued to ACTUAL factory spec, and thus, early head gasket failure in the field.

How to torque your Cylinder and Head bolts properly:

- Make SURE the threads are clean, both on the head bolts, and the threads in the block.

- Apply a small amount of lubricant to the threads and lightly grease the bottom of the head of the bolt

- Torque the 4 M10 cylinder bolts, in a criss cross pattern, making sure to do this in a 2 stage operation of:

- First Stage: 30 Nm (22.1 lbf ft)

- Second Stage: 60 Nm (44.3 lbf ft)

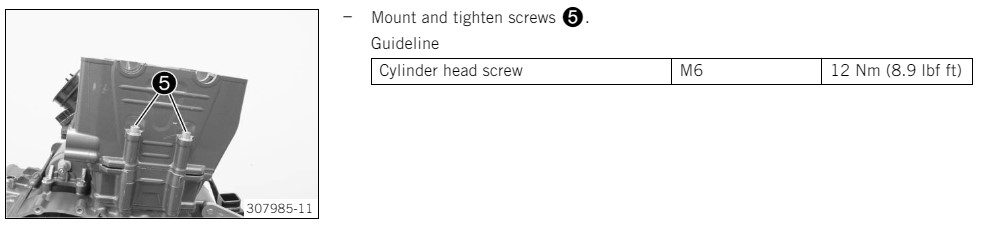

- Tighten the 2 M6 camchain side cylinder bolts to 12 Nm (8.9 lbf ft)

- Now STOP! Wait! Let those 6 bolts sit, at torque, for AT LEAST 5 MINUTES. Yes, really. This is IMPORTANT! Go and get something cold to drink, and just... wait.

- OK, time is passed, only NOW will you will re-Check to torque values of the bolts to ensure that the 6 bolts are are still torqued to the same torque numbers. If the bolt stretched, they will turn before you reach the 60nm or 12nm numbers they were set at. So if any move, pull those bolts and toss em! They are garbage and NOT to be trusted. Replace any bad bolts. This can happen even with brand new bolts! Don't TRUST any of them. Verify. If you have to replace any of the bolts, remove the other bolts, and start the tightening squence again from the beginning!

My bike is running hot

Many riders think their bikes run hot because the temp gauge is "high" at 2 bars from the top. This is actually the normal operating temperature of the bike. The engineers at KTM don't follow our expected convention of "normal" to be in the middle of the range. Unless your bike is pegging the temp gauge and flashing the overheat warning, or the ECU shuts off the motor, your bike is not too hot. The ECU should shut down the motor before damage occurs if things are otherwise working correctly.Coolant

Engine Ice and Water Wetter

Engine Ice and Water Wetter are essentially Distilled Water and Ethanol Alchohol. The Ethanol lowers the freezing point of water, but contributes NOTHING to cooling. Water Wetter DOES include some anti-corrosion additives, so adding 2 capfulls of it can be helpful.Standard Coolant

Standard Coolant works VERY well. Standard coolant however contains glycol, which is very slippery if spilled on a track surface. As such, race organizations and tracks disallow standard coolant to be used as a safety factor.Distilled Water

Straight distilled water is the BEST coolant possible. Engine ice is essentially ethanol alcohol. As long as you don't need to worry about freezing, run straight water.Many think Engine Ice or Water Wetter is the very best coolant. The reason why these coolants may work slightly better is because the mix ratio of water to additive is less than the 50:50 ratio of standard coolant to water. Straight water however will always outperform ANY other coolant because it's 100% coolant. The ratio of other additives only serves to protect against freezing temps, and contribute nothing to cooling capacity.

You will NEVER see a head to head comparison of cooling capacity for any coolant vs straight water, because it would be soundly beat. That said, add 2 capfulls of Water Wetter for it's anti-corrosion additives.

Street vs Race

Racebikes

Run straight distilled water. Period.Streetbikes

Run standard coolant. Period.If you are overheating a street RC390, you have a problem OTHER than you coolant. You have a problem with your:

- Cooling fan

- Radiator

- Thermostat

- Air in your cooling system

- Coolant amount / Low coolant

- Water Pump / Impeller damage

- Head Gasket

Front End Springs

Upgrading the front end to ditch the VERY poor choice Bajaj picked for the US market is a common modification.Disassembly

This is a tricky one, unfortunately. Bajaj used RED loctite that releases at 250C (or 500F) but it's an aluminum cap and steel cylinder. Ugh! They NEVER intended the fork lower to be disassembled. So, it's gonna be tricky. You need to use heat to get them apart, but you ALSO can't use so much that you soften the aluminum. You ALSO have the problem that you have to get a LOT of heat in FAST, so you don't melt the plastic parts in the shim stack, but not SO fast that you overshoot the temperature. Propane alone ain't going to do it, or at least not easy. I've seen FAR too many try and use their propane torch, melt their internals, and then email me asking if I have space parts... because... thanks KTM!!! You can NOT buy the parts from them. Double Ughhhh! Which means, you need to find someone who's installed a cartridge kit, and DIDN'T screw theirs up in the process. You will also require a pin wrench to get the cap out. Some have tried using a pair of vice grips on the small edge of the aluminum cap. It might work, but honestly... use a pin wrench. I use a propelyene and oxygen torch to heat forks when I do them. You can also try to use MAPP gas (yellow bottle, not blue) but you HAVE to have a large burner to dump enough BTUs in fast enough. I heat the fork leg, not the cap itself. The cap is aluminum, it'll absorb the heat all on it's own... getting the fork leg to 250c is what you are trying to do. You want to go fast, but again, NOT overshoot 500c. If the aluminum softens... well, we are back to looking for a donor replacement.Bajaj also has saved up one more trick for us! When the factory installs them, the do so with a power tool. This means that they all too frequently over torque the cap, cross thread it, or even worse it's dirty so they gall the cap threads to hell when it's installed. So you might be at the right temp, but it still isn't unscrewing! All you can do there is musle into it. Unfortunatly. Most pin wrenches aren't up to the task. If the temp is right, and there is no galling or cross threading, AND they didn't torque the cap down SUPER tight, a standard pin wrench will unthread the cap easily. So... check you temp (have one person who's SOLE job is heating, one who's job is temp monitoring, and a third who is responsible for unscrewing. The heater can also be the person who holds the fork if you don't have a clamp or vice to hold it while the unscrewer threads the cap out with the pin wrench. Yeah... it can be difficult. it's just the way it is. If Bajaj had used a steel cap, it would be no drama at all... but no, they used aluminum. 6061 as near as I can tell. Fsckers!!!

They are apart!!! Now what?

There are two options here:- Cartridge Kit from K-Tech or Andreani - This will run you somewhere in the ballpark of $1200-$1500

- Straight Rate Springs - You can drop in straight rate springs for your rider weight, and run with oil level and oil viscosity. This will run you around $200

Springs and Oil

Springs and Oil are my recommendation for the vast bulk of riders? Why? It's cheaper, and it's NOT that big of a deal to do. Really! Most riders that use cartridges set the preload, compression, and rebound, and then they might as well weld those settings in place because they NEVER touch then again, if they do at all.Which springs

You are going to use the spring rate to set the major damping force for the forks. The rate you use is both based on rider weight, and target use. Racers will need stronger speeds because they are traveling at higher rates of speed. Remember that F=ma formula you learned back in Highschool Physics... well, here's where it comes into play. :) Street riders can get away with lower spring rates, as they are going to (at least rarely) accidently clip the curbing at 105mph. So, racers will likely need something in the 1.0 to 1.2kg rate. Street riders will rarely need anymore more than 1.1kg. That said, you can make up for softer springs with more preload and higher viscosity oil, or if you have harder springs go with less preload and a thinner wt fork oil. These are tunable parameters, and there is no one "correct" answer as every rider has a setup they prefer. Which settings will you like? I don't know. You may not "know" but you'll feel it and you can adjust from there.Set your Sag

Setting the sag / preload is done with a spacer that you cut from 1" Schedule 40 ABS. You are aiming for a total spacer + springs length to be equal to the stock 350mm length. So, if your springs are say 270mm long, then you want an 80mm long spacer. 270 + 80 == 350. Got it? Basically, disassemble the forks, drop in the new springs, drop in your spacer, assemble the forks DRY, mount them on the bike, and check your sag. If you are a heavy rider, the bike not have much, or maybe even any, sag. Anything from 0 to 10mm is the target for static sag. Aim for something in the middle of around 5mm static sag. Then, Rider sag. For Rider Sag, you want to target something between 20 and 30mm. This is the important one! There however is no "CORRECT" sag amount. Every rider is different, and every rider prefers their own setup for the feedback they want from the bike and how they want the bike to perform. Some like a slow soft predictable suspension. Some want their fillings knocked out it's so firm. Many want something in the middle. Some have no idea what they want they just want it to work and don't feel comfortable with getting into the internals... but really, you CAN do this! It's NOT a big deal. Honestly. Anybody can learn this stuff, and I'm HAPPY to answer questions and help, but it's easier than you might think it is. Really! REALLY! OK, so, you set your spacer until you have a good target sag number. This might take you 1 to 3 attempts, but because they are assembled dry, it's easy enough to take the front end back apart again. 15 minutes, tops. If you have too much sag, use longer spacers. If you don't have enough sag, use longer spacers. Easy. Might take a few tries, but it only takes a few minutes for each attempt, so just go in knowing you may have to do it more than once. OK, so, now you have your sag set. What's next?Fork oil!

To tune your suspension, you are going to have two variables to play with.- Oil Viscosity - For most riders a 7wt fork oil is what you want to go with. The factory uses a 4w fork oil which isn't sufficient for US riders. We are larger in stature, and need more damping. If you are especially big (300# in gear) then you might want to consider going with a 9w oil.

- Oil Amount - Stock amount of oil to use is 460ml per fork leg, so one bottle of fork oil should do you for both forks. Fork oil costs about $20 for decent fork oil. I get mine on Amazon. I prefer to use Belray High Performance Fork Oil, but run whatcha want. Maxima, Motul, Yamaha, Honda, Ohlins, RockShox... lots of options, but I like using Belray because I can blend the oils to make pseudo wt mixes... so if I want a 6wt, I can mix 50/50 of 5wt and 7wt, and bingo... 6wt. It's really that easy. If I want a 7.5wt I can mix 5wt and 10wt... and viola, 7.5wt..

- Oil Level / Air Spring - To tune the suspension further, you can adjust the oil level / amount of "Air Spring" in the fork by adding more oil to stiffen the forks initial travel more, or reduce the oil level some to add more air spring and soften up the initial travel. We are talking adjusting the amount by say 10-15ml here. It's not a lot.

When you have your oil sorted out, then you are going to loctite the fork leg lower. Use BLUE loctite, NOT the RED! I prefer the chapstick style Loctite 248. It never spills, and never gets old. Small sticks are cheap, but this is a single cylinder bike. It's vibrates, a LOT!!! Use that stuff on EVERY fastener. EVERY ONE! If you loosen a bolt, use 248 on it before you put it back in. Period. These bikes will shake themselves to bits if you let 'em, so don't let em! :)

Shock Swap

A very common upgrade people do for their rear suspension is to ditch the stock POS rear shock, and replace it with a shock from a Yamaha R6 or R1.

Model year shocks

The model years which are applicable are the 99-02 R6 and the 07-08 R1 shocks. For first gen RC390 and Duke 390's which have the exhaust located between the swingarm and the motor, the R6 shock fits with no modifications to the bike.For 2nd gen models which have a right side exhaust can, or those wanting to use an R1 shock, the shock can still be fitted, but you have to modify the swingarm. There are raised fins on top of the lower shock mount on the swingarm. For the shock to fit, you need to take an angle grinder and grind down the raised fins so the shock can fit. If the shock is fit in a standard upright orientation, less modificaiton is required to get it to fit.

If you have a 2nd gen exhaust with the right exit can, you have to run the shock in an inverted orientation. The shock does not care which orientation it is in, as it's not an emulsion shock (IE there is a reservoir and the nitrogen is contained inside of a bladder and does not mix with, aka create an emulsion with, the shock oil. Any shock that has a remote reservoir (or internal reservoir but those are less common) can be oriented in any direction. Emulsion shocks must be oriented upright. This is similar to how the front suspension works, where there is nitrogen (or air) which has direct contact with the oil. This can allow the oil to absorb the air, and create a foam / emulsion, which reduces the viscosity of the suspension. That's why they have an orientation, and why the oil level needs to always be above the shock or fork internals. Anyway, inverted orientation, is no problem. Works just the same as if it were upright. So don't worry! :)

How to mount the shock

OK, back to how to mount the R1 shock. You need to grind down the fins to be even with the flat of the shock mount, and face the reservoir to the rear. You'll need to create a bushing, or use a stack of washers, to put on the bolt to center the shock. This is so it can not slide side to side, and so that the bearings in the shock mount remain free of debris. That is what those fins on the shock mount do, to try and keep road grime away from the pivot point.So what does it mean after you ground those fins off... well it means that some road grime may have an easier way to get into the bolt and shock eye. It's going to anyway, but it's something worth considering. Meaning, you might need to take a peek at that bolt every 50k miles or so. Most bikes will never see that many miles anyway, and those that do tend to be regularly maintained so this isn't a large burdeon to add to the other regular maintenance. If you ride in the rain and muck, you might need to look at it more frequently. If you only ride in the dry and not on dirt and gravel roads, don't worry about it. Make sense? Use your common sense here. It's a pivot surface, so... inspect it every so often, just like you (should) do with all of the other ones. OK? OK! Use some common sense for maintenance, and it'll be just fine. :)